Reverse Circulation Drilling

An efficient, accurate and proven technique for large-diameter boreholes

About

Reverse Circulation Drilling Expertise

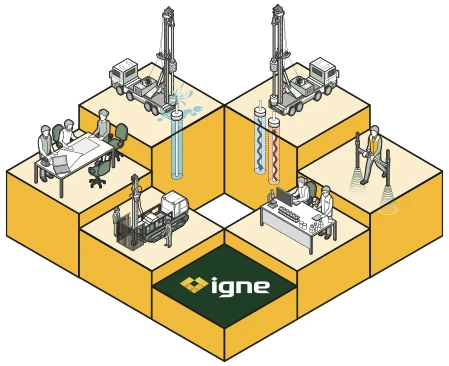

At Igne, we understand every drilling project requires a method matched not only to the ground conditions but also to the sampling and operational needs of the client.

Reverse circulation drilling is one such technique. It’s highly effective for creating large-diameter boreholes, particularly in unconsolidated or variable formations.

Our expert drilling teams deploy this method to deliver accurate, efficient and safe drilling solutions across the UK.

Explainer

What is reverse circulation drilling?

Reverse circulation drilling is a method where drilling fluid or water flows down the annulus, or outer space, between the drill pipe and the borehole wall. The drilling cuttings are carried back up to the surface through the centre of the drill pipe.

This flow is the opposite of direct circulation drilling, where fluid is pumped down the drill pipe and returns up the borehole annulus.

The reverse flow design provides several operational advantages, including maintaining borehole stability, improving sample quality and enabling drilling in a wide range of ground conditions.

It is especially suited to projects requiring large-diameter boreholes in loose or unconsolidated materials.

The Reason

Why is Reverse Circulation Drilling Used?

Reverse circulation drilling was developed to overcome the challenges of drilling in loose or unstable formations where borehole collapse or sample contamination can occur. It is widely used where large boreholes are required and where reliable, uncontaminated samples are essential.

At Igne, we often recommend reverse circulation drilling for water borehole construction, environmental wells, exploratory drilling and other projects where borehole integrity and sample quality cannot be compromised.

The Benefits

Key benefits of Reverse Circulation Drilling

Reverse circulation drilling offers a number of significant advantages over other drilling methods:

- efficient sample recovery without contamination from overlying formations

- effective in unconsolidated and loose formations where other methods may be less reliable

- excellent borehole stability due to the hydrostatic pressure in the borehole annulus

- reduced need for heavy drilling mud or filter cakes

- accurate identification of water strikes during drilling

- suitability for large-diameter boreholes where high sample volumes are needed

- safer working conditions through efficient cuttings removal and stable borehole walls

The Process

How Does Reverse Circulation Drilling Work?

In reverse circulation rotary drilling, the drill bit advances into the formation while drilling fluid or water is pumped down the annulus between the drill pipe and borehole wall.

Cuttings are carried back up the drill string and removed at the surface.

The drill bit is positioned only a few centimetres ahead of the annulus to minimise disturbance and ensure accurate sample recovery. Dual-walled drill pipes are often used, with an outer pipe for fluid circulation and an inner pipe for cuttings removal.

Specially designed bits, including rock-roller bits and hammer drills with air lift systems, enable effective drilling and cuttings transport.

At the surface, cuttings are separated from the return fluid for analysis or disposal. This method ensures that samples are representative of the formation just drilled and are not contaminated by materials from other depths.

The Delivery

When is Reverse Circulation Drilling the Best Choice?

It is particularly valuable when:

- drilling in unconsolidated or variable ground conditions

- constructing water wells that require large-diameter bores

- environmental sampling where sample integrity is critical

- drilling to moderate depths up to around 300 metres

- projects require minimal borehole wall invasion and clear water strike identification

The Experts

Igne’s Reverse Circulation Drilling Expertise

We have decades of experience in delivering reverse circulation drilling projects throughout the UK. Our drilling teams are fully trained and equipped to operate advanced reverse circulation rigs.

We manage the complete drilling process, from initial planning and ground investigation to borehole construction, development, testing and reporting.

Our services are underpinned by rigorous health, safety and environmental standards. We provide clients with clear, accurate data and reliable outcomes, ensuring that every project benefits from the highest standards of technical excellence and operational efficiency.

FAQ

Frequently Asked Questions about Reverse Circulation Drilling

- What is reverse circulation drilling used for?

It is primarily used for creating large-diameter boreholes, especially in loose or unconsolidated formations. It is suitable for water boreholes, environmental wells and projects requiring accurate sampling.

- What ground conditions are suitable for reverse circulation drilling?

It performs well in unconsolidated and variable formations, such as sands, gravels and silts. It can also be used in some consolidated formations, though other methods may be more efficient for hard rock.

- How deep can reverse circulation drilling go?

Depths of up to 300 metres are typical, depending on ground conditions, borehole diameter and project requirements.

- How does reverse circulation drilling maintain borehole stability?

The hydrostatic pressure of the water column in the borehole annulus supports the borehole walls, reducing the risk of collapse without needing dense drilling mud or filter cakes

- Does reverse circulation drilling provide good quality samples?

Yes. Because cuttings are returned directly up the drill pipe without passing through overlying formations, samples are generally free from contamination.

- Is reverse circulation drilling cost-effective?

While the initial setup may be more expensive than some conventional rotary methods, the efficiency, sample quality and reduced risk of borehole failure often result in overall cost savings.

- Why choose Igne for reverse circulation drilling?

We offer national coverage, advanced equipment, experienced drilling teams and a commitment to safety, quality and client satisfaction. Our tailored solutions deliver reliable results across a wide range of projects.

The Next Step

Contact Igne for Reverse Circulation Drilling Solutions

When it comes to drilling large-diameter boreholes in challenging ground conditions, reverse circulation drilling provides the accuracy, efficiency and reliability you need. At Igne, we combine technical expertise with practical experience to deliver drilling solutions that meet the specific needs of your project.

Our teams are ready to assist with everything from initial consultation to drilling, development, testing and reporting. Whether you are planning a new water borehole, require environmental sampling or need expert advice on drilling methodologies, we are here to help.

Contact Igne today to discuss your reverse circulation drilling requirements and discover how our expertise can support the success of your project.

Artesian Boreholes

Angle Boreholes

Drilling with Mud

Large Diameter Boreholes

Deep Boreholes

Acidisation

Hydrofracturing

Dewatering

Monitoring Boreholes

Vibrating Wire Piezos

Fibre Optics

Seismic Monitoring

Deep Wireline Coring

Gas Control

Deep Soakaways

Decommissioning

Specialist Plant & In Hole Equipment Hire