Fibre Optic Monitoring

Deployment of fibre optic sensors within boreholes for monitoring temperature, strain or acoustic signals.

About

Fibre Optics

Fibre optic technology is revolutionising how we monitor ground movement, pore pressure, temperature and strain in critical infrastructure and complex ground conditions. With the ability to gather real-time, high-resolution data across long distances and harsh environments, fibre optic systems are becoming the go-to solution for proactive risk management in construction and geotechnical engineering.

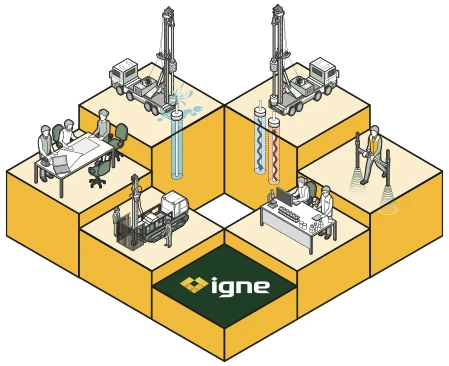

At Igne, we bring together decades of specialist drilling expertise and cutting-edge monitoring capabilities. Our team is skilled in the installation of fibre optic cables in boreholes, trenches and structural elements, ensuring optimal performance of distributed sensing systems from the very start

The uses

Why Use Fibre Optic Monitoring?

Fibre optic monitoring allows for distributed sensing, meaning that data can be collected continuously along the entire length of the fibre rather than at fixed points. This gives a detailed picture of how ground or structural conditions are evolving in real time.

Common applications include:

- Detecting ground movement along embankments, slopes and tunnels

- Monitoring settlement or heave in foundations and retaining walls

- Measuring temperature changes for geothermal or environmental studies

- Monitoring strain and stress in structural components

- Early warning systems for landslides or ground failure

- Permanent monitoring of sensitive infrastructure assets

Fibre optics are especially well suited to large-scale or remote sites where traditional point sensors would be too costly or impractical to deploy and maintain.

The science

How Does Fibre Optic Monitoring Work?

Fibre optic cables use light to measure physical changes along their length. Technologies such as Distributed Temperature Sensing (DTS), Distributed Strain Sensing (DSS) and Distributed Acoustic Sensing (DAS) interpret how the light is reflected or scattered when the fibre is subjected to strain, temperature changes or vibration.

Because the cable itself is the sensor, a single fibre optic line can replace hundreds of conventional sensors, collecting data at intervals as small as every metre, or even centimetre.

The installation

Specialist Drilling for Fibre Optic Installation

Correct installation is critical to the performance of any fibre optic system. That’s where we come in! Our specialist drilling experience makes the difference. We work with system designers, geotechnical engineers and contractors to install fibre optic cables in ways that ensure maximum sensitivity and long-term stability.

Our approach may involve:

• Drilling boreholes to the required depth and specification

• Carefully placing fibre optic cable within the borehole or trench

• Applying backfill or grout mixes suited to the sensing application

• Installing protective casing or conduit where needed

• Ensuring precise depth control for targeted monitoring zones

• Terminating cables in accessible monitoring enclosures or nodes

We’re also experienced in installing hybrid systems that combine fibre optics with traditional piezometers or inclinometers to give a more complete picture of ground behaviour.

The benefits

Advantages of Fibre Optic Monitoring

Fibre optic systems offer a host of benefits that make them ideal for demanding monitoring scenarios:

- High-resolution, real-time data across long distances

- Extremely durable and immune to electromagnetic interference

- No need for local power at the sensor

- Reduced long-term maintenance costs

- Flexible installation in boreholes, trenches, structures and slopes

- Integration with data loggers, software and alert systems

Whether you’re monitoring for deformation, strain, temperature or vibration, fibre optic technology delivers robust performance in even the harshest conditions.

The end

What Happens When Monitoring Ends?

At the end of a project, fibre optic systems can often remain in place to provide ongoing asset monitoring, or they can be decommissioned depending on the client's requirements. If cables are installed in boreholes, Igne can safely grout and seal these in accordance with best practice guidelines, ensuring that there is no ongoing environmental risk.

FAQ

Frequently Asked Question about Fibre Optic Monitoring

- What is fibre optic monitoring used for?

Fibre optic monitoring is used to measure strain, temperature, vibration, and ground movement across infrastructure, geotechnical, and environmental sites. It provides continuous, real-time data along the entire length of the fibre, making it ideal for slope stability, embankments, tunnels, retaining walls, foundations, and utility corridors.

- How does fibre optic monitoring work?

It works by sending pulses of light down a fibre optic cable. When the fibre experiences changes in strain, temperature or vibration, it alters the light signal. These changes are picked up and analysed using technologies such as Distributed Temperature Sensing (DTS), Distributed Strain Sensing (DSS), and Distributed Acoustic Sensing (DAS).

- Why is fibre optic monitoring better than traditional sensors?

Unlike traditional sensors that measure only at fixed points, fibre optics give distributed data across the entire cable length. This enables high-resolution monitoring over hundreds or even thousands of metres. It also means fewer components, lower maintenance, and better performance in harsh or remote environments.

- What types of projects use fibre optic monitoring?

Common applications include:

- Slope stability and landslide detection

- Settlement and heave in structures and ground

- Tunnel and retaining wall deformation

- Pipeline and utility corridor monitoring

- Geothermal or ground temperature measurement

- Structural health monitoring on bridges and dams

- Can fibre optics be installed in boreholes?

Yes; Igne regularly installs fibre optic cables in boreholes to monitor deep ground behaviour. This provides vertical profiles of temperature or strain that are critical for understanding subsurface performance and movement.

- How deep can fibre optic cables be installed?

Cables can be installed to depths exceeding 100m, depending on project needs. Igne uses rotary or sonic drilling to reach target zones and ensures the correct backfill or grouting is applied for accurate sensing and long-term durability.

- What is required to install a fibre optic monitoring system?

Installation typically involves:

- Specialist drilling (if monitoring below ground)

- Placement of the fibre optic cable in boreholes, trenches or structures

- Proper backfill to ensure sensitivity and protection

- Connection to an interrogation unit or data logger

- Integration with software for data analysis and remote access

We manage the full installation process, ensuring the system is configured for performance from day one

- Can fibre optic monitoring be combined with other sensors?

Absolutely. Fibre optic cables can be installed alongside piezometers, inclinometers, seismic sensors, or vibrating wire instruments in the same borehole or trench. This gives a comprehensive view of ground behaviour and structural performance.

- What’s the lifespan of a fibre optic monitoring system?

When installed properly, fibre optic systems can last 20 years or more. They have no moving parts, are highly resistant to corrosion and electromagnetic interference, and require minimal maintenance.

- Is fibre optic monitoring expensive?

Initial setup costs may be higher than traditional point sensors, but the long-term value is greater. You get more data, lower maintenance, and the ability to detect problems early, reducing risk, delays and potential repair costs down the line.

- How is the data accessed and used?

Data is accessed via a central interrogation unit, which can be connected to a local server or a remote platform. Alerts can be set up to notify stakeholders of any threshold exceedance. The data can support compliance, design validation, real-time decision-making and long-term asset management.

- Does Igne supply and install the full system?

Igne specialises in the drilling and installation of fibre optic cables as part of distributed monitoring systems. We work closely with sensor manufacturers and monitoring consultants to ensure the installation matches the system requirements and delivers optimal performance.

The next step

Fibre Optic Installation Experts

Fibre optics may be smart, but they still rely on expert hands to install them correctly. At Igne, we’re known for our precision in specialist drilling, ground investigation and instrumentation. Our team understands both the technology and the ground, enabling us to install fibre optic systems with absolute confidence.

We operate across infrastructure, energy, environmental and construction sectors - and whether you need to monitor a railway embankment, a deep shaft or a contaminated land site, we have the tools and the knowledge to deliver.

If your project demands high-quality, continuous monitoring data from below ground or within a structure, fibre optic technology is the answer - and Igne is the team to install it.

Get in touch with our expert drilling and instrumentation specialists today to discuss how fibre optics could transform your approach to monitoring.

Artesian Boreholes

Angle Boreholes

Drilling with Mud

Large Diameter Boreholes

Deep Boreholes

Acidisation

Hydrofracturing

Dewatering

Monitoring Boreholes

Vibrating Wire Piezos

Fibre Optics

Seismic Monitoring

Deep Wireline Coring

Gas Control

Deep Soakaways

Decommissioning

Specialist Plant & In Hole Equipment Hire