Deep Wireline Coring

Wireline coring is a specialist drilling technique used to recover continuous core samples from significant depths below ground level.

About

Wireline Coring

It plays a vital role in geotechnical, geological, mineral exploration, environmental and infrastructure projects, allowing engineers and scientists to gain a detailed understanding of the subsurface conditions over extended vertical profiles.

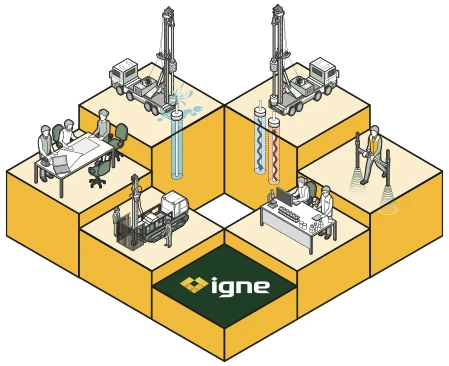

At Igne, we are experts in deep wireline coring, offering precision drilling services across a wide range of sectors.

Our highly experienced teams use advanced rotary coring rigs and bespoke tooling to deliver high-quality, continuous core recovery, even in complex geological formations or technically demanding locations.

Whether your project requires deep coring for mineral exploration, geological modelling, slope stability assessment or foundation design, Igne delivers results you can rely on.

The uses

What Is Deep Wireline Coring Used For?

Deep coring provides continuous, cylindrical samples of the ground from depths that can exceed hundreds of metres. These intact core samples are essential for understanding lithology, stratigraphy, structural geology and hydrogeology. Wireline coring is typically used for:

- Mineral exploration and resource evaluation

- Geotechnical investigation for infrastructure and tunnelling

- Landslide and slope stability assessments

- Contaminated land characterisation

- Foundation and pile design for large structures

- Geological and hydrogeological research

- Carbon capture and storage feasibility

The ability to retrieve complete samples from depth gives clients a more accurate and nuanced view of what lies beneath the surface, improving both design reliability and environmental risk assessment.

The process

How Does the Deep Wireline Coring Process Work?

Wireline coring is most often carried out using rotary coring methods. Igne deploys high-performance rigs capable of operating in a wide range of ground conditions and at considerable depth. Igne match the rigs capabilities including pullback and head speed to the drilling systems to be used and the anticipated geological conditions.

The coring bit, embedded with industrial-grade diamonds, cuts a circular path through the subsurface, allowing the core barrel to collect a column of intact material. Different matrix bits are utilised depending on the geology encountered. The harder the rock, the softer the matrix of the bit that is utilised. This matrix wears down faster, exposing more diamonds to cut the rock.

Depending on the ground conditions and project requirements, we may use double or triple tube core barrels to maximise recovery and preserve sample integrity. Our high pressure pumps, drilling fluids and additives are carefully selected to ensure minimal disturbance and optimal core preservation.

Core samples are then logged, photographed, and securely boxed, ready for laboratory testing, structural analysis or visual inspection by the client or consultants.

The benefits

Advantages of Deep Wireline Coring

The core benefits (pun intended) of deep coring include:

- Continuous sample recovery from significant depths

- High-quality, undisturbed core for laboratory testing and analysis

- Improved geological and geotechnical understanding

- Precise identification of geological boundaries and features

- Accurate input data for design, modelling and risk assessment

By working with Igne, you also benefit from our broader expertise in ground investigation, instrumentation and monitoring, giving you a complete view of the ground conditions and how they may affect your project.

minimising risks

Challenges & Considerations

Deep coring is a technical process that requires specialist equipment, trained operators and meticulous planning. Challenges can include:

- Access to remote or restricted sites

- Difficult or mixed ground conditions

- Groundwater control and drilling fluid management

- Core recovery in fractured or weak strata

- Transport and preservation of long-length core sections

Igne brings the experience and equipment to overcome these challenges efficiently and safely. We tailor every project to the site conditions and client requirements to ensure high recovery rates and minimal disruption.

FAQ

Frequently Asked Questions about Deep Wireline Coring

- How deep can Igne core?

We routinely undertake coring to depths exceeding 500 metres and can go deeper depending on the scope, geology and rig access. Each project is assessed individually to ensure the most appropriate drilling approach.

- What size cores are typically recovered?

Common core diameters range from 50mm (NQ size) to over 100mm depending on the tooling and purpose. Larger diameters are often used for geotechnical and structural testing. Wireline systems available and commonly used are Geobor S, PQ, HQ and NQ. Conventional systems are available as required.

- What happens to the core once it is recovered?

Core samples are logged, photographed, and placed in durable, labelled core boxes. They can be transported to our laboratory for further geotechnical, chemical or structural testing, or retained for client inspection.

- Do I need permits to drill deep cores?

Permitting requirements depend on location, land ownership, depth, and whether groundwater or protected geology is involved. Igne can guide you through the permitting process and ensure compliance with all regulatory standards.

- Can deep coring be combined with other investigations?

Yes, core holes can be used for piezometer installation, gas monitoring, packer testing or geophysical logging after core recovery and other in situ testing as required. This integrated approach maximises the value of the borehole.

- Is deep coring noisy or disruptive?

While it involves plant and machinery, Igne uses rigs with small footprints and low-noise engines wherever possible. We manage logistics carefully to minimise disruption, particularly in sensitive or urban environments.

The Experts

Contact Igne today to discuss your deep coring requirements

With decades of experience and a team of highly trained specialists, Igne is the partner of choice for deep coring projects across the UK. From planning to execution and post-coring analysis, we offer a turnkey solution that delivers quality, precision and insight from the ground up.

Discover how we can help you uncover the full story beneath your site.

Artesian Boreholes

Angle Boreholes

Drilling with Mud

Large Diameter Boreholes

Deep Boreholes

Acidisation

Hydrofracturing

Dewatering

Monitoring Boreholes

Vibrating Wire Piezos

Fibre Optics

Seismic Monitoring

Deep Wireline Coring

Gas Control

Deep Soakaways

Decommissioning

Specialist Plant & In Hole Equipment Hire