Large Diameter Boreholes

Drilling for Scale and Performance

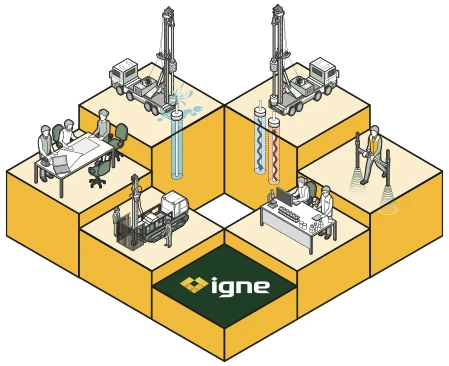

About

Drilling at Scale

Large diameter boreholes play a crucial role in specialist drilling projects, enabling high-volume water abstraction, deep foundations, geothermal systems, and complex infrastructure development.

Drilling at this scale requires precision, expertise, and the right equipment to ensure success. At Igne, we specialise in large diameter borehole drilling, providing bespoke solutions to meet the demands of major projects across multiple sectors.

Explainer

What Are Large Diameter Boreholes?

A large diameter borehole is generally classified as any borehole with a diameter exceeding 300mm. However, in some applications, boreholes of over 600mm or even 1 metre in diameter are required.

These boreholes serve a range of purposes, from deep dewatering wells to structural foundations and geothermal energy extraction.

Drilling boreholes at this scale presents unique technical challenges, requiring robust drilling rigs, advanced methodologies, and experienced specialists who understand how to overcome geological complexities.

Igne has the expertise and equipment to ensure large diameter boreholes are drilled efficiently and safely.

The Reasons

Why Are Large Diameter Boreholes Needed?

The primary reason for drilling large diameter boreholes is to accommodate applications that require significant flow capacity, stability, or structural integrity. They are essential for projects where smaller boreholes would be insufficient, such as:

- Water Supply Boreholes requiring high abstraction rates

- Geothermal Wells for district heating and cooling

- Deep Foundations & piling for large structures

- Dewatering Systems for mines, tunnels, and construction sites

- Monitoring Wells for environmental and geological assessments

Large diameter boreholes provide greater operational efficiency in these applications, ensuring long-term performance and durability.

The Uses

Who Needs Large Diameter Boreholes?

A range of industries and organisations require large diameter boreholes to support critical infrastructure and environmental management, including:

• Water utility companies for high-capacity water abstraction

• Geothermal energy developers for district heating networks

• Civil engineering firms for foundation piling and ground stabilisation

• Mining and tunnelling companies for effective site dewatering

• Environmental consultants for large-scale groundwater monitoring

Igne works with clients across all these sectors, delivering specialist drilling solutions tailored to their specific needs.

Weighing it up

Pros & Cons of Large Diameter Boreholes

Advantages

- High flow rates for water abstraction and geothermal applications

- Increased structural stability for piling and deep foundation work

- Better access for inspection, maintenance, and monitoring

- Enhanced dewatering capacity for large-scale projects

Challenges

- Higher costs compared to standard boreholes due to increased drilling time and materials

- More complex drilling operations requiring specialist equipment and expertise

- Potential for greater geological and hydrological risks that need careful management

With Igne’s experienced drilling teams, these challenges can be efficiently managed, ensuring that large diameter boreholes are drilled to the highest standards.

The Process

How Are Large Diameter Boreholes Drilled?

Drilling large diameter boreholes requires a methodical approach to maintain borehole stability and ensure efficiency. The process typically involves:

- A thorough site assessment to determine ground conditions and potential risks

- Selection of the appropriate drilling technique, such as rotary, cable percussion, or auger drilling

- Use of drilling muds or casing to stabilise the borehole during drilling

- Continuous removal of cuttings to maintain borehole integrity

- Installation of the required borehole lining or casing to support long-term stability. Including selection of appropriate casing materials, wall thicknesses and grouting methods

Igne’s expert drilling teams carefully plan and execute every stage of the process, ensuring successful borehole completion with minimal disruption.

The challenge

Specialist Equipment & Challenges in Large Diameter Drilling

Drilling large diameter boreholes requires heavy-duty equipment capable of handling the additional stresses and loads involved. Specialist rigs, large-diameter drill bits, reinforced casing systems, contract crane lifts and high-powered mud circulation pumps are often necessary to support drilling operations.

Key challenges include:

- Ensuring borehole stability in weak or unconsolidated formations

- Managing high volumes of cuttings and drilling fluids

- Overcoming artesian pressures or unexpected groundwater conditions

- Drilling efficiently while minimising costs and environmental impact

- Mitigating any ground gas risks

- Installation of fully grouted large diameter and deep casing often by contract crane lift

- Management of a large scale site

With our extensive experience and industry-leading equipment, Igne is well-equipped to handle these challenges, delivering reliable and effective large diameter borehole solutions.

FAQ

Frequently Asked Questions About Large Diameter Boreholes

- What is considered a large diameter borehole?

A borehole is generally classified as large diameter if it exceeds 300mm, with some projects requiring boreholes of 600mm or more.

- Why would a project need a large diameter borehole?

Large diameter boreholes are essential for applications requiring high water flow, deep structural foundations, or geothermal heat extraction.

- What drilling methods are used for large diameter boreholes?

Techniques such as rotary drilling, cable percussion drilling, and auger drilling are commonly used, depending on ground conditions and project requirements.

- Are large diameter boreholes more expensive?

Yes, they typically require more time, materials, and specialist equipment, but they provide significant operational and structural benefits that justify the cost.

- What challenges come with drilling large diameter boreholes?

Challenges include borehole stability, cuttings removal, groundwater management, and ensuring efficient drilling rates.

- Can Igne provide specialist support for large diameter drilling?

Absolutely. Igne has the expertise, equipment, and experience to handle large diameter borehole projects across multiple sectors.

The Next Step

Need Expert Large Diameter Borehole Drilling? Contact Igne Today

Drilling large diameter boreholes requires skill, experience, and the right equipment to ensure success. Whether your project involves high-capacity water abstraction, deep foundation piling, or geothermal energy, Igne is the trusted specialist drilling partner you need.

Get in touch today to discuss your requirements and discover how our expert drilling solutions can support your project.

Artesian Boreholes

Angle Boreholes

Drilling with Mud

Large Diameter Boreholes

Deep Boreholes

Acidisation

Hydrofracturing

Dewatering

Monitoring Boreholes

Vibrating Wire Piezos

Fibre Optics

Seismic Monitoring

Deep Wireline Coring

Gas Control

Deep Soakaways

Decommissioning

Specialist Plant & In Hole Equipment Hire