Drilling & Lining

Precision drilling and robust lining for reliable water wells

About

Water Well Drilling & Lining

Drilling and lining are two of the most important steps in the installation of a water well. The drilling process creates the borehole that provides access to groundwater, while the lining ensures the structural integrity of the well and protects the water supply from contamination.

Whether for domestic, agricultural, or industrial use, a well must be expertly drilled and correctly lined to function efficiently for decades. At Igne, we have the knowledge, experience, and technology to drill and line water wells in any geology across the UK, ensuring sustainable and secure water access.

The process

The Drilling & Lining Process

Drilling a water well is not a one-size-fits-all approach. The method used depends on factors such as the depth of the aquifer, the geology of the site, and the intended water usage. Igne selects the most appropriate technique to ensure efficiency, cost-effectiveness, and long-term reliability.

- Rotary Drilling: one of the most common methods for deep wells, rotary drilling uses a rotating drill bit to cut through rock and sediment. This is effective for a range of geological conditions, including hard rock formations.

- Cable Percussion Drilling: a tried-and-tested technique, cable percussion drilling is ideal for softer ground and layered sediments. It’s often used in areas with clay, sand, or gravel deposits.

- Down-the-Hole Hammer (DTH) Drilling: best suited for drilling through hard rock, DTH drilling uses a percussive hammer to break through tough geological layers while maintaining borehole stability.

- Auger Drilling: typically used for shallow wells, auger drilling is fast and efficient in loose soils or weathered rock.

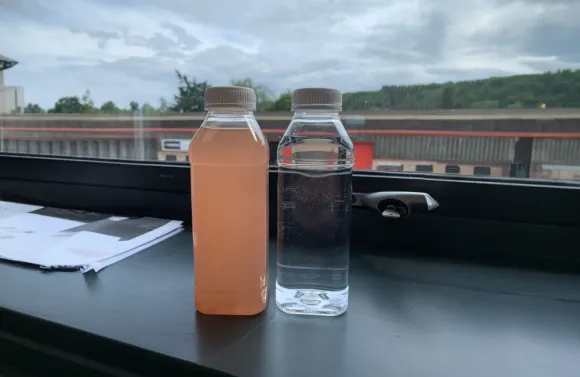

Once the borehole is drilled, lining (also referred to as casing) is installed to support the well structure and maintain water quality. Different casing materials are used depending on the geology and regulatory requirements:

- Steel Casing: highly durable and suitable for deep wells, steel casing offers excellent strength, particularly in unstable ground conditions. Igne can use certifiable repurposed steel casing for clients prioritising sustainability which provides a huge carbon saving over new. Igne can assist with the casing specification to meet design life.

- PVC Casing: corrosion-resistant and lightweight, PVC casing is commonly used in wells with minimal geological instability.

- Stainless Steel Casing: often used in environments where water quality is critical, stainless-steel casing prevents contamination and ensures a long lifespan.

The lining process also includes installing well screens to allow water to enter while preventing sediment from clogging the system. Gravel packs may be placed around the casing to improve filtration and stabilise the well structure.

Borehole Lining

Why Lining is Critical for a Long-Lasting Water Well

Without a properly installed lining, a well can suffer from structural failure, contamination, and poor water yield. Unlined wells can deteriorate over time, causing structural failure and requiring costly repairs.

Proper casing prevents surface contaminants from seeping into the groundwater supply, and a well-designed lining system improves water flow and reduces sediment intrusion, ensuring optimal performance.

High-quality casing and proper installation techniques mean wells can remain functional for decades with minimal maintenance.

Trust experience

Drilling & Lining Expertise in Every Geological Condition

The UK has some of the most geologically diverse ground conditions in the world, ranging from soft sediments in river valleys to complex limestone karst systems and hard igneous rock. Successfully drilling and lining a water well requires an in-depth understanding of these varying ground conditions, and that’s where we excel.

With extensive experience in ground investigation and specialist drilling across the UK, Igne has encountered and overcome every geological challenge. Whether dealing with collapsing sands, fractured rock, or aggressive groundwater chemistry, we apply tailored solutions to ensure every well meets the highest standards of durability and performance.

Trust expertise

Why Choose Igne for Your Water Well Drilling & Lining?

With a long track record of successful projects across all types of terrain, Igne ensures wells are drilled and lined to the highest standards. We also offer the use of repurposed steel casing, contributing to environmental sustainability without compromising performance.

From initial feasibility studies to final installation, we manage the entire process, ensuring seamless execution, and we follow all relevant regulations and industry standards, ensuring every well meets environmental and legal requirements.

No two wells are the same, and we design solutions specific to your water needs and site conditions.

FAQ

Frequently Asked Questions About Water Well Drilling & Lining

- How deep should my water well be?

The depth depends on local groundwater conditions and your intended use. Domestic wells may be 30–100 metres deep, while commercial wells can exceed 200 metres.

- How long does it take to drill a water well?

The timeline varies depending on geology, depth, and drilling method. Most wells can be completed within a few days to a few weeks.

- What type of casing should I use?

The best casing material depends on the site's geology, water chemistry, and well depth. Steel, PVC, and stainless steel are common options, each with different advantages.

- Can I use my well without lining?

Unlined wells are prone to collapse and contamination. Casing is essential for a safe, long-lasting well.

- Does Igne provide maintenance services for drilled wells?

Yes, we offer ongoing support, including pump servicing, water quality testing, and well rehabilitation if needed.

- Is it possible to drill a well in an area with complex geology?

Yes, Igne specialises in drilling in challenging conditions, using advanced techniques to ensure a successful outcome.

- How can I ensure my well remains operational for years?

Regular maintenance, proper casing installation, and good drilling practices ensure a long lifespan. Igne provides expert guidance on well upkeep and rehabilitation.

- Can a water well reduce my reliance on mains water?

Absolutely. A well can provide a sustainable and cost-effective water source for homes, farms, and businesses.

The next step

Trust Igne for Water Well Drilling & Lining

From initial drilling to the final lining installation, Igne ensures your borehole is built for long-term performance. With a deep understanding of UK geology, sustainable casing options, and a commitment to quality, we deliver wells that stand the test of time.

No matter your location or geological challenges, Igne has the expertise to drill and line your well efficiently and effectively.

Contact us today to take the first step toward securing your independent water supply with a professionally installed, high-performance well.

Licencing Applications

Drilling & Lining

Water Treatment

Water Analysis

Test Pumping

Borehole Pumps

Borehole Design

Abstraction Borehole Real Time Digital Monitoring Systems

Drilling Consultancy

Pump Installation