Borehole Design

A well-designed borehole is the foundation of a reliable and long-lasting water supply.

About

Designing Boreholes

Whether for domestic, agricultural, or industrial use, the success of a borehole depends on careful planning, engineering, and expert design.

At Igne, we provide bespoke borehole design solutions, ensuring that every system is tailored to the site’s geology, water demand, and intended usage. With our extensive experience in drilling, hydrogeology, and water well engineering, we design boreholes that maximise efficiency, minimise environmental impact, and ensure sustainable water extraction.

getting it right

Why is Borehole Design Important?

Borehole design is not just about drilling a hole in the ground, it’s about creating an optimised system that delivers consistent, high-quality water for decades. Poorly designed boreholes can lead to low yield, pump failures, contamination risks, and increased operational costs.

A properly designed borehole ensures:

- Sufficient & Sustainable Water Yield: The borehole must be deep enough and correctly positioned within the aquifer to provide a reliable supply.

- Structural Integrity: A robust casing, filter screen, and well-constructed borehole prevent collapse and maintain long-term performance and ensure long design life.

- Efficient Pump Operation: correct borehole diameter and depth ensure the right pump is selected, reducing energy costs and wear.

- Protection from Contamination: proper sealing and casing prevent pollutants from entering the water supply.

- Compliance with UK Regulations: ensuring the borehole meets all water abstraction, environmental, and safety regulations.

Design structure

Key Factors in Borehole Design

Each borehole is unique, and several critical factors determine the design process:

1. Site Assessment & Hydrogeological Survey

Before drilling begins, Igne conducts a detailed hydrogeological survey to assess the following:

- Groundwater Availability: ensuring the aquifer can provide sufficient water yield.

- Geological Formations: identifying suitable drilling depths and rock layers.

- Potential Contamination Risks: checking for nearby sources of pollution (e.g., septic tanks, industrial waste).

2. Borehole Depth & Diameter

- Depth: borehole depth depends on the location of the aquifer and the required yield.

- Diameter: the borehole must be wide enough to accommodate the pump, casing, and any filtration systems.

3. Borehole Casing & Screens

- Casing: protects the borehole structure and prevents contamination.

- Screens: allow water to flow in while filtering out sand, silt, and debris.

4. Sealing & Grouting

To prevent contamination from surface water and pollutants, boreholes require grouting and sealing around the casing.

5. Pump Selection & Placement

A borehole’s efficiency relies on using the right pump type, capacity, and positioning. We ensure the pump is:

- Correctly sized for the borehole depth and yield.

- Positioned at the optimal depth to maximise efficiency.

- Equipped with a variable speed drive (VSD) if necessary to regulate flow rates.

Eliminating risks

Common Mistakes in Borehole Design & How Igne Avoids Them

- Drilling too Shallow. Insufficient depth can lead to seasonal drying or contamination risks.

- Oversizing the Borehole. An unnecessarily large borehole increases costs without improving performance.

- Undersizing the Borehole. A borehole of too small a diameter won’t allow a pump of a sufficient size to be installed. This will limit the maximum yield available to be pumped from the borehole.

- Poor Casing Selection. Inadequate materials lead to borehole collapse or contamination.

- Incorrect Pump Sizing. Overpowering the pump can cause excessive energy costs, while an underpowered pump can fail to deliver the required flow.

- Ignoring Maintenance Access. A poorly designed borehole may be difficult to inspect or repair in the future.

Igne designs boreholes with efficiency, longevity, and sustainability in mind, ensuring optimal performance from day one.

The Process

The Borehole Design Process at Igne

-

Site Assessment: hydrogeological survey and feasibility study.

-

Design Planning: determining borehole depth, diameter, casing, and screens.

-

Regulatory Compliance: ensuring adherence to UK water abstraction and environmental laws.

-

Drilling & Construction: executing the borehole drilling according to the design plan.

-

Pump Installation: selecting and fitting the most suitable pump for efficiency and performance.

-

Testing & Commissioning: test pumping and water quality analysis before the borehole goes into full operation.

FAQ

Frequently Asked Questions About Borehole Design

- How deep should my water borehole be?

Depth depends on groundwater availability and intended usage. We conduct surveys to determine the optimal depth.

- What size should my borehole be?

The diameter depends on the required yield and pump size. A typical borehole ranges from 100mm to more than 300mm in diameter.

- Can an old borehole be redesigned or upgraded?

Yes. If a borehole is underperforming, Igne can assess it and recommend improvements or upgrades.

- Can an old borehole be redesigned or upgraded?

Yes. If a borehole is underperforming, Igne can assess it and recommend improvements or upgrades.

- How long does borehole design take?

The process varies but typically includes surveys, planning, and regulatory approvals before drilling begins.

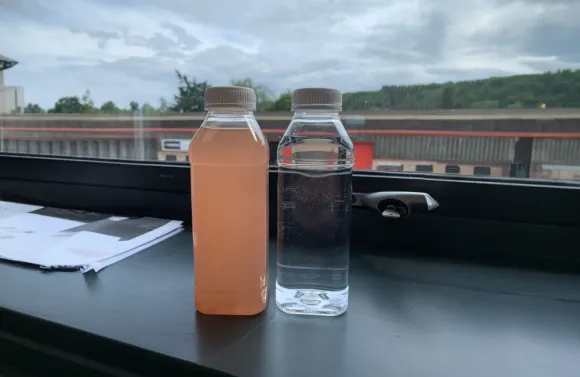

- Does borehole design affect water quality?

Yes. A well-designed borehole prevents contamination and ensures consistent water quality.

The Next Step

Why Choose Igne for Borehole Design?

Igne brings decades of expertise in borehole drilling, hydrogeology, and water well design, ensuring each project is tailored to the client’s specific needs. From feasibility assessments to full system implementation, our borehole designs guarantee maximum efficiency, reliability, and compliance with UK water regulations.

Ready for us to design you a borehole that delivers long-term performance?

Contact Igne today to discuss your project and get expert advice on borehole design, construction, and optimisation.

Licencing Applications

Drilling & Lining

Water Treatment

Water Analysis

Test Pumping

Borehole Pumps

Borehole Design

Abstraction Borehole Real Time Digital Monitoring Systems

Drilling Consultancy

Pump Installation