Borehole Pumps

A borehole is only as effective as the pump that extracts water from it. Choosing the right borehole pump is essential for ensuring a consistent, efficient, and sustainable water supply.

About

What do borehole pumps do?

Whether your borehole serves a domestic household, agricultural irrigation, or an industrial facility, the correct pump will maintain water pressure, optimise energy use, and extend the lifespan of your borehole system.

Igne specialises in borehole pump selection, installation, and maintenance, ensuring that your system delivers reliable performance year after year.

Useage

Why Are Borehole Pumps Necessary?

A borehole pump is the key component that lifts water from underground to where it is needed. Without a pump, a borehole is simply a water source that cannot be accessed!

Selecting an appropriate pump ensures:

- Consistent water pressure, providing a steady flow to taps, irrigation systems, or industrial processes.

- Efficient energy use, preventing excessive power consumption and lowering running costs.

- Minimal wear and tear, extending the lifespan of the borehole by maintaining optimal flow rates.

- Reliable operation, preventing failures that could leave homes, farms, or businesses without water.

Choose Quality

Types of Borehole Pumps

Igne supplies and installs a range of high-quality borehole pumps, suited to different depths and flow requirements. Here’s a summary:

Submersible Pumps

These are the most common type, submerged in the borehole and pushing water to the surface. These are ideal for deep boreholes and offer excellent reliability and efficiency.

Centrifugal Pumps

These can be used for shallower boreholes where water is closer to the surface, offering high flow rates.

Solar-powered Borehole Pumps

These are an eco-friendly solution for remote locations where electrical supply is limited.

Variable Speed Drives (VSD) Pumps

These are designed to adjust power consumption based on demand, improving energy efficiency and prolonging pump life.

Permanent Magnet Motor Borehole Pumps

These motors run with a reduced power consumption which provide both a carbon and running costs saving. For large abstraction boreholes this can amount to a significant saving in running costs.

Which Pump?

Choosing the Right Borehole Pump

Selecting the right pump depends on several factors, including borehole depth. Deeper boreholes require submersible pumps with higher lift capacity.

Required flow rate is another consideration. The volume of water needed per hour or day dictates the pump’s power.

Whether the pump will be electric, solar-powered, or run on an alternative source is a consideration for some. As is the fact that if the water contains high sediment levels, a pump with enhanced durability and filtration may be needed.

We conduct detailed assessments to ensure the best borehole pump is selected for your needs, preventing inefficiencies or unnecessary costs.

The Process

Borehole Pump Installation & Maintenance

Proper installation and ongoing maintenance are key to ensuring a borehole pump operates efficiently for years to come.

Professional Installation:

- Ensuring the pump is positioned at the correct depth for maximum efficiency.

- Correctly sizing the pump for the borehole and demand requirements.

- Installing appropriate control systems to regulate pressure and flow.

- Ensuring compliance with UK water regulations and safety standards.

Ongoing Maintenance:

- Regular checks on pump performance, pressure, and energy consumption.

- Inspection of pipes, fittings, and electrical connections.

- Cleaning and servicing to prevent blockages or mechanical failure.

- Replacing worn components before they lead to a system breakdown.

Signs that your borehole pump needs servicing or replacement include:

- Reduced water flow

A sudden drop in pressure could indicate blockages, pump wear, or electrical faults. - Intermittent supply

If the pump turns on and off unpredictably, there may be an issue with controls or power supply. - Unusual noises

Grinding or rattling sounds can indicate pump deterioration or sediment build-up. - Higher energy bills

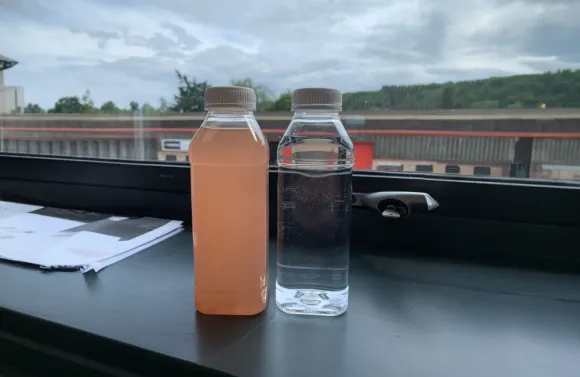

A failing pump may be working harder than necessary, leading to increased power usage. - Poor water quality

If water appears discoloured, contains sediment, or has an unusual taste or odour, the pump may need attention.

FAQ

Frequently Asked Questions About Borehole Pumps

- How long does a borehole pump last?

With proper maintenance, a high-quality borehole pump can last 10 to 15 years, depending on usage and environmental conditions.

- Can I install a borehole pump myself?

It is not recommended. Professional installation ensures correct sizing, positioning, and compliance with UK water regulations.

- How do I know which pump is right for my borehole?

Igne assesses borehole depth, flow rate, and water demand to recommend the most suitable pump for your needs.

- What happens if my borehole pump stops working?

Common causes include electrical faults, motor failure, or blockages. We provide rapid diagnosis and repair services

- Do borehole pumps require regular maintenance?

Yes. Routine checks can prevent unexpected failures and prolong the lifespan of your system.

The Next Step

A borehole is an investment

Choosing the right borehole pump ensures you get the most from your water supply. Igne provides expert pump selection, professional installation, and ongoing maintenance services, ensuring your system runs efficiently and reliably.

Whether you need a new pump, an upgrade, or emergency repairs, Igne is here to help.

Contact us today to discuss your borehole pump requirements and ensure a dependable water supply for years to come.

Licencing Applications

Drilling & Lining

Water Treatment

Water Analysis

Test Pumping

Borehole Pumps

Borehole Design

Abstraction Borehole Real Time Digital Monitoring Systems

Drilling Consultancy

Pump Installation