Concrete Testing British Standards

Why concrete testing to British Standards matters. Igne delivers UKAS-aligned sampling, curing and testing to reduce risk and ensure long-term performance.

Concrete doesn’t usually fail suddenly. When problems occur, they tend to develop quietly - starting with small quality issues early in a project that go unnoticed, untested or unchallenged.

That’s why concrete testing to British Standards matters. It’s how designers, contractors and asset owners move from assumption to certainty.

What concrete testing achieves

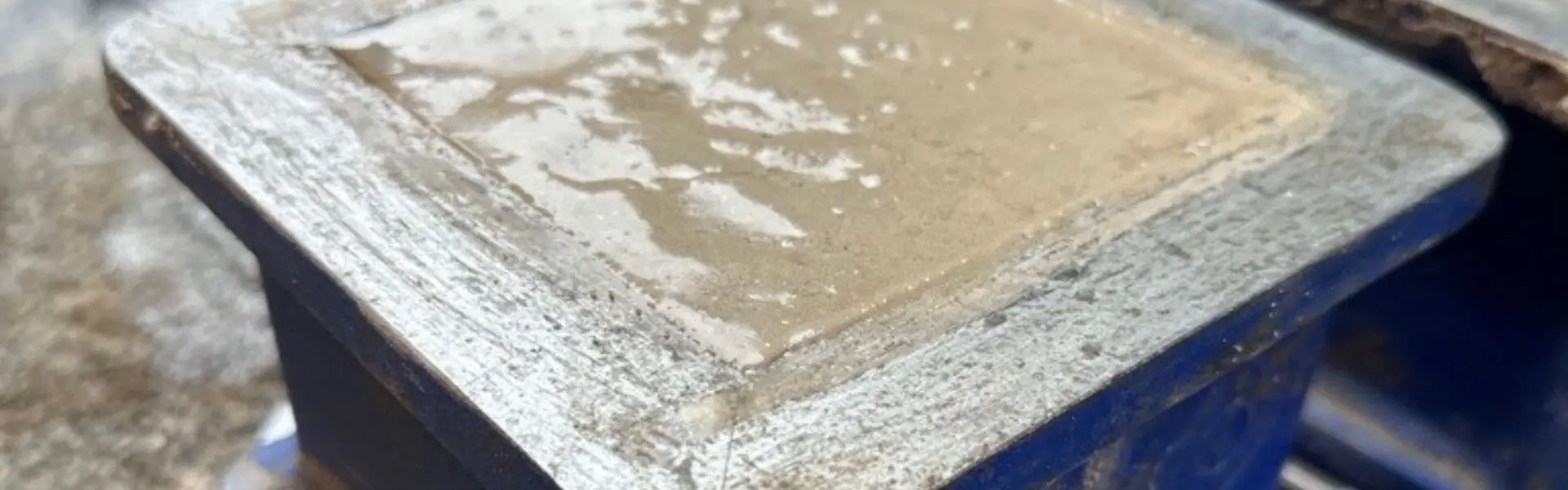

Testing concrete isn’t just about breaking cubes in a lab. It’s about confirming that what arrives on site is what was specified, and that it will perform as intended for years, often decades, to come.

British Standards such as BS EN 12390, BS 1881 and BS 8500 set out how concrete should be sampled, cured and tested so results are meaningful, consistent and defensible.

When those standards are followed properly, testing provides confidence that:

- the concrete mix matches the design intent

- strength develops as expected

- durability requirements have been met

- long-term performance risks are understood and controlled

Where things can go wrong with concrete

Concrete testing is only reliable if it is carried out correctly at every stage.

Poor sampling, inconsistent curing or non-standard testing procedures can all produce misleading results - giving a false sense of security or, just as problematic, raising unnecessary concerns.

These early-stage errors are often the root cause of later disputes, remedial works or reduced asset life.

How Igne approaches concrete testing

At Igne, our approach is deliberately simple: control the process, follow the standards, and deliver data our clients can rely on.

We carry out concrete testing in accordance with recognised British Standards, with strict procedural control from the moment a sample is taken through to final reporting.

That includes:

- Representative sampling and fresh concrete testing, confirming workability and consistency on delivery

- Controlled curing environments, removing variables that affect strength development

- Accurate compressive strength testing, using calibrated equipment and UKAS-aligned procedures

- Durability and specification checks, including exposure and chloride classes

- Full traceability, with clear chain-of-custody and auditable records

Why concrete testing to British Standards matters for your project

Concrete is often out of sight - buried in foundations, enclosed within structures or covered by finishes. Once it’s in place, problems are difficult and costly to fix.

Testing to British Standards provides reassurance at the point when decisions can still be made. It supports compliance, protects programme certainty and reduces long-term risk for everyone involved.

In conclusion, concrete testing isn’t about ticking a box.

It’s about achieving complete confidence - in the material, the structure and the asset’s future performance.

Our role is simple: deliver accurate, defensible, standards‑compliant data that supports safe construction and long‑term asset integrity. Whether it’s routine cube testing, mix verification, or complex durability assessments, Igne provides the technical confidence that projects depend on.